TILE & STONE WORKS SHOWROOMS ARE OPEN

CLICK HERE FOR THE STERLING HEIGHTS SHOWROOM | (586) 991-5835

CLICK HERE FOR THE SHELBY TOWNSHIP SHOWROOM | (586) 254-1234

WE ARE NOW KEEPING OUR REGULAR HOURS IN THE SHOWROOMS AND WAREHOUSE

ONE ON ONE SALES AND DESIGN CONSULTATIONS

DRIVE UP LOADING

FREE LOCAL DELIVERY

586-991-5835

586-254-1234

Florida Brick & Clay Company

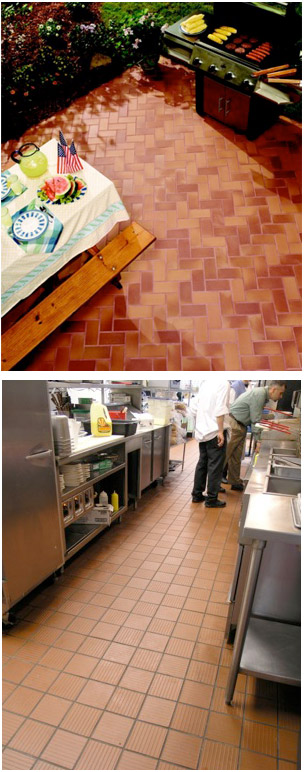

Quarry Tile and Brick Pavers

Tile & Stone Works’ manufacturer for quarry tile and brick pavers is the Florida Brick & Clay Company. Extruded quarry tile and pavers are some of the most widely used and durable flooring products available. Made right here in the USA specifically for floor applications demanding the highest performance in terms of durability, sanitation, and classic looks.

High traffic commercial kitchens, industrial applications, exterior porches, driveways, and walkways in residential and commercial projects are all great places for quarry tile and brick pavers. Florida Brick & Clay Company’s high quality products can be found in many of the most popular restaurants and retail stores. Chances are if you have been out shopping or had lunch at a fast food restaurant you walked across a FBC’s products. For cost effective and durable hard surface flooring quarry tile is tough to beat.

Company Profile.

In April of 1963, the Azorin brothers, Rogelio, Manolo, and Antonio, began their quest for the "American Dream". Three years before, they had been forced to leave all their property and belongings behind as Fidel Castro nationalized all businesses and seized all private property in Cuba.

When they left Cuba in 1960, they had hopes that Castro would not stay in power very long. They would be able to return and reclaim their business and property, which included a state-of-the-art clay sewer pipe plant, and brick plant. After a couple of years working in a brick and pipe plant in Georgia, it became clear to them that their stay in the United States might be more than temporary. That led to a decision to start anew and Florida Brick & Clay Company, Inc. was born in Plant City, Florida.

The company began making full-size facing bricks and clay drain tiles. Raw materials had to be brought in by rail from Georgia and Alabama. Due to the high cost of shipping shale and clays, the brothers developed a 1/2 inch veneer facing brick which could be used to simulate brick, but required much less clay to produce. A traditional shuttle kiln was used to fire the products.

In 1970, they made a major decision to modernize the grinding and batching plant and a new more efficient tunnel kiln was built. As it turned out this decision to modernize was a turning point in the business as costs were lowered with the increase in production capacity. Florida Brick & Clay began carving a niche in the marketplace with its introduction of a 1/2 inch thick, wire-cut brick paver sold under the brand name Sunshine Pavers®. A major boost in sales, as well as credibility, was gained when McDonald's® Restaurants began using the pavers on their patios and walkways. The brick pavers are durable and skid-resistant, even when wet, which make them ideal for exterior applications, such as pool decks, patios, walkways and driveways.

The Sunshine Pavers product line has grown to eleven colors, including earth tones, cream, gray, brick red, two wood-grains, flashed colors and the newest addition, antique Colonial Blend. With its quality and product innovation, Florida Brick & Clay has long been considered the leader in the “wire-cut brick paver market.

In 1984, the next major expansion took place as FBC built a plant to produce quarry tile using a flat-punched extrusion process. This product was sold under the brand name of AmeriCraft® Tile. Not satisfied with the quantity or quality of production, the plant was modernized in 1991 and the method of production was changed to the split-tile process. The quality of the quarry tile was dramatically improved and a new line of colors was introduced as AmeriCraft® II Tile.

Extruded from shale and fireclays, giving them "through-the-body" color, and fired at very high temperatures, AmeriCraft® II Tiles have low porosity and long lasting durability. They are produced in 4x8, 6x6 and 8x8 sizes and come in six attractive colors. The red and the gray colors are also available in an abrasive texture. Their durability makes them an excellent choice for use in residential or commercial applications with heavy foot traffic.

Florida Brick & Clay also produces a high quality pool coping. It is available in six colors that complement the pavers and quarry tiles and is 2" x 3 5/8" x 8" in size. The pool coping has a cushioned radius edge, unlike traditional brick coping, making it less likely to harm someone climbing out or sitting on the side of a pool. FBC has captured a major share of the market with its high quality pool coping.

The second generation of Azorins is now carrying on the family business. They are intent on continuing the tradition of quality and innovation that has made Florida Brick & Clay Company the success it is today.